Precision That Prints True.

Resin and wax 3D printing, precision scanning, and dimensional verification — every model prepared under Apex supervision for a flawless casting.

Every great finish begins with a perfect print.

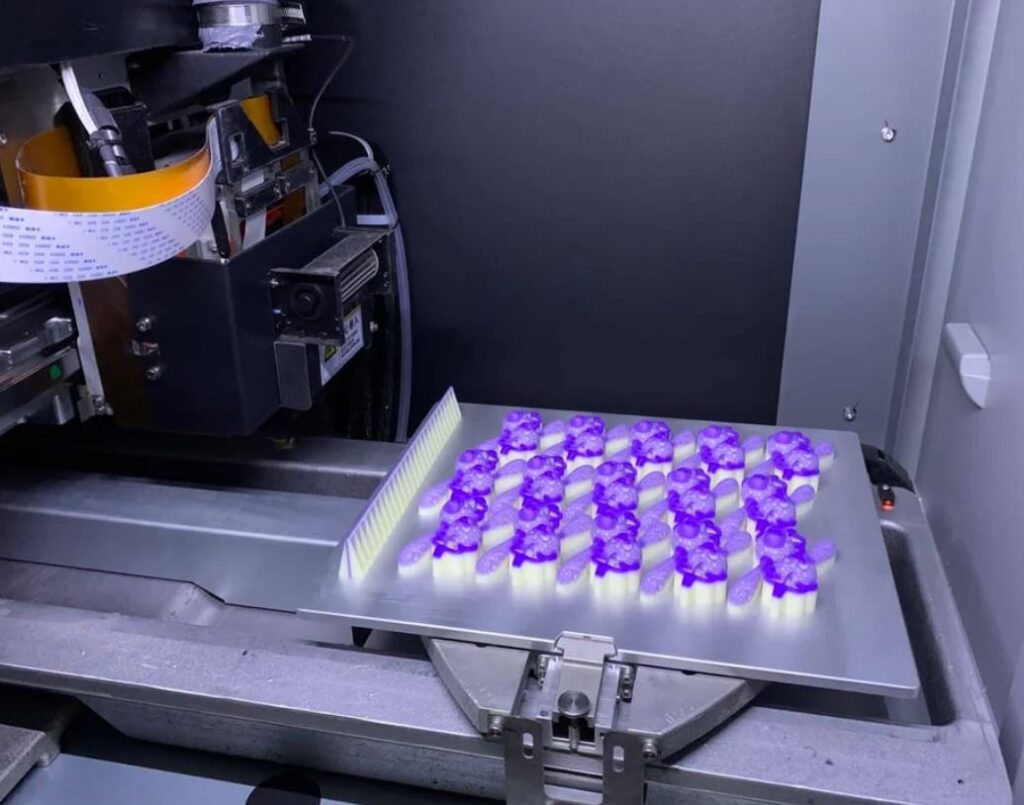

Every casting is only as good as the print it starts from.

We produce high-resolution resin and wax prints with clean supports, consistent density, and dimensional accuracy that eliminates rework.

Each model is scanned and verified before moving to production — ensuring the geometry you approved is the geometry that arrives in metal.

Seamless from file to form

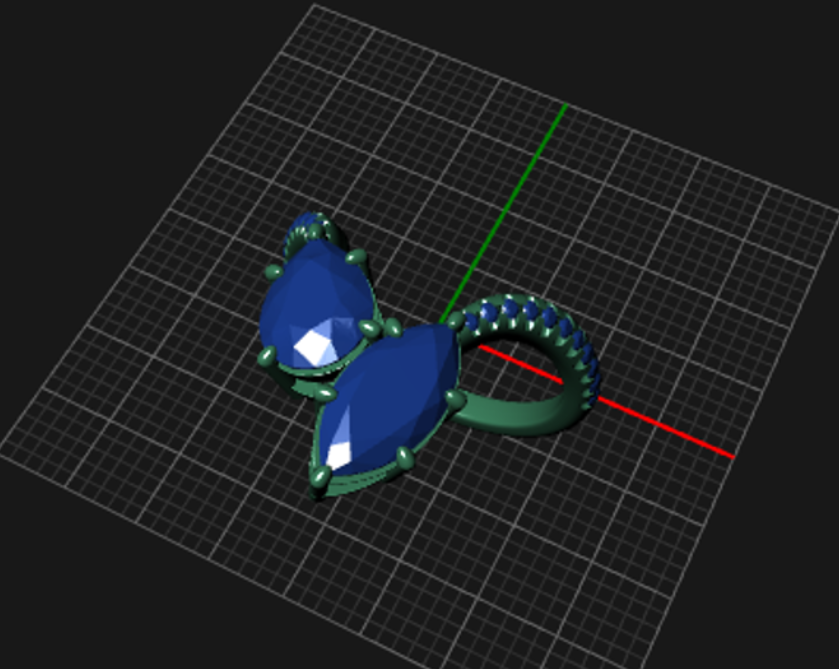

CAD Review

We inspect your CAD file for wall thickness, support strategy, and print orientation.

3D Printing

Each design is built in high-detail resin or castable wax, calibrated for precision down to microns.

3D Scanning

We capture and compare every printed model against the CAD data, confirming scale and symmetry before casting.

Precision saves time — and reputation.

A clean print means a cleaner casting.

Tight tolerances prevent seat gaps, reduce polishing loss, and keep your stones fitting right the first time.

That’s why Apex controls every model — from file integrity to print verification — so your clients see only perfection.

After print verification, the piece moves into the Diamond Setting & Finishing stage — where precision meets craftsmanship, and every stone finds its seat.