Setting the Standard in Precision

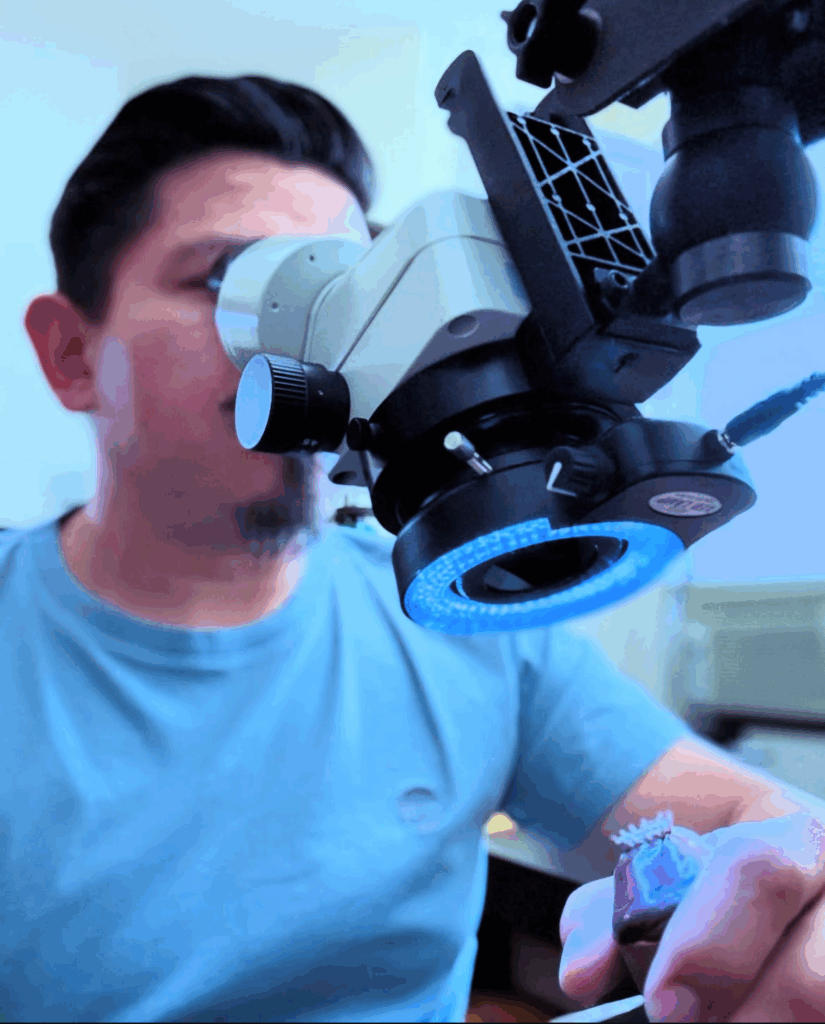

Every stone placed under microscope accuracy.

Each polish, plating, and final check handled in-house — so what leaves Apex is production-perfect and ready to showcase.

Precision doesn’t end at design

There’s no software here — only steady hands, patience, and a microscope.

I cut every seat and shape every claw to exact tension, checking alignment and symmetry until the piece is ready for polish.

Perfection isn’t opinion — it’s measurement.

Perfection Lives in the Details

Finishing decides whether a piece looks handmade or manufactured.

I refine every surface, restore every edge, and balance the metal tone so what leaves my bench doesn’t just meet expectations — it resets them.

The precision that starts in 3D Printing & Scanning carries through every stage — from the first layer to the final reflection.

Start with design. End with perfection.

From CAD to polish, every stage is handled under one standard — mine.

No handoffs, no guesswork, no excuses.

Just precision that carries through from the first render to the final reflection.